Brand Name: COORIG

Model Number: ADL-2S-1250

Place of Origin: Tianjin, China (Mainland)

Condition: New

Type: Pipe Production Line

Pipe Material: Galvanized steel

Application: HVAC industry

Production Capacity: 13m/min

Voltage: 380V 3PH

Power(W): 13kw

Dimension(L*W*H): 2500x1800x1500mm

Weight: 3500kgs

Certification: ISO9001

Warranty: 1 Year

After-sales Service Provided: Engineers available to service machinery overseas

Width of the sheet(mm): 1250mm

Max-working speed(m/min): 13

Thickness(mm): 0.5-1.2mm

type: air conditioner duct equipment

Diameter of the frame can be adjusted: by hand

Screen touched: by hand or keyboard input

Coiler max-weight(kg): 7000

The length of the error: 0.5mm

Diagonal error: 0.8mm

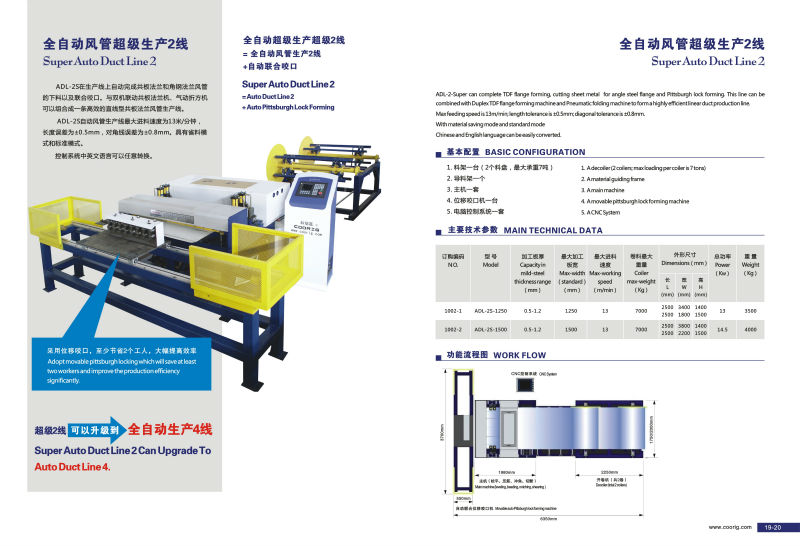

Super auto duct line 2 can complete TDF flange forming, cutting sheet for angel steel flange and pittsburgh lock forming.

air conditioner duct equipment

Main features:

Super auto duct line 2 can complete TDF flange forming, cutting sheet metal for angel steel flange and pittsburgh lock forming. This line can be combined with Duplex TDF flange forming machine and Pneumatic folding machine to form a highly efficient linear production line.

Max feeding speed is 13m/min, length tolerance is +-0.5mm; diagonal tolerance is +-0.8mm.

with material saving mode and standard mode

Chinese and English language can be easily converted.

Basic configurations:

* A material frame(2 coils, the max loading per coil is 7tons)

* A transmission frame

* A main machine

* A movable pittsburgh lock forming machine

* A CNC System

Our Logo:

We have a after-sale service, Warranty 12 months

· After service and maintenance

· The equipment after technical service , the installing , operation , maintenance we supply good technical

consulting service , user can through telephone or Web ( QQ ,MSN .email ,remote assistance ,trade manager and other way )

to communicate with our technical department . Supplier ensure give the feedback in 24 hours after

received the question . If the telephone or the remote assistance can't solve the problem , supplier will arrange

our engineer to come to user scene for equipment maintenance.